Two Components Liquid LSR Silicone Rubber Transparents Color High Resistance Tear Strength Food Grade Medical for Pacifiers Baby Care Silicone Products Making

Description

Basic Info.

| Model NO. | GTSIL-P00-P30 |

| Transport Package | 1kg, 20kg, 25kg, 200kg/Drum |

| Trademark | GT Silicon |

| Origin | Dongguan |

| HS Code | 39100000 |

| Production Capacity | 500tons Per Month |

Product Description

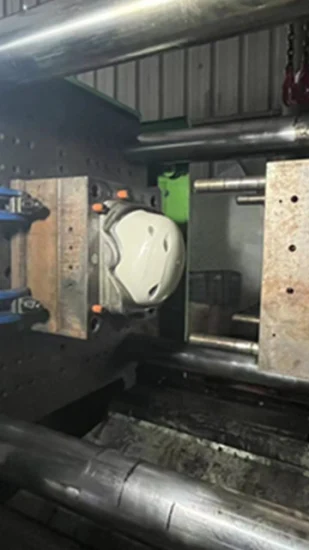

Product DescriptionGTSIL-P series silicones are two compounds, liquid, with the mixing ratio of 1:1 ( or 10:1) , it's also called addition cured silicone rubber that have exceptional tear strength and working properties, cured in room temperature. There are a wide range of applications for GTSIL-P series platinum silicone rubber. 1. Industry mold making : plaster, gypsum, concrete, stones, wax, jewelry, polyurethane, polyester resin etc. 2. Food grade mold making: cake ,candy ,chocolate etc.Technical Datasheet

| Model Code | GTSIL-P00 | GTSIL-P5 | GTSIL-P10 | GTSIL-P15 | GTSIL-P20 | GTSIL-P25 | GTSIL-P30 | GTSIL-P35 | GTSIL-P40 |

| Hardness - Shore A | 0 | 3-5 | 8-10 | 14-16 | 18-20 | 24-26 | 28-30 | 34-36 | 38-42 |

| Viscosity - Cps | 1500-2200/6000-7000 | 1500-2200/6000-7000 | 1500-2200 | 2000-3000 | 2000-3000 | 2000-3000 | 4000-5000 | 6000-8000 | 8000-10000 |

| Mixing Ratio - % | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

| Tear Strength - KN/m2 | 5-6/7-9 | 7-9/10-12 | 15-18 | 16-19 | 20-23 | 23-25 | 20-23 | 18-22 | 14-17 |

| Tensile Strength - Mpa | 2-3 | 2.5-3.5 | 3.5-4.5 | 3.5-4.5 | 4-6 | 4-6 | 4-6 | 4-6 | 3.5-5.5 |

| Shrinkage - % | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% | 0.1% |

| Elongation - % | 500-600% | 650-850% | 600-800% | 600-800% | 500-600% | 400-500% | 400-500% | 400-500% | 350-450% |

Outstanding release properties High flowability and long working timeHigh tear strength & tear strength High elasticity, for easy removal of complex replica partsCan add thixotropic for vertical surface application

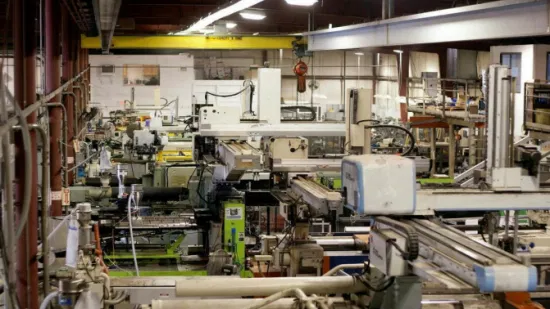

Dongguan Gangtian Polymer Materials Co.,Ltd, located in Dongguan City, Guangdong Province, China, is a professional leading manufacturer of RTV 2 Liquid Silicone Rubbers. Focusing our Research and Development on innovation, we have been providing performance enhancing solutions to serve the diverse needs of thousands of customers worldwide since the year of 2003. Our main products include RTV 2 mold making series, tinsil and platsil, RTV 2 platsil for products, injection LSR, silicone potting compound, silicone oil, silicone ink, etc. With penetrating Professionalism in technology solutions and Honesty in after service, we GT Polymer Materials Co., Ltd are not only a trustworthy partner but also a good friend to the customers worldwide.Brand Story - Gangtian, founded in 2003 in Dongguan, by Yuanfu Deng, a Chinese chemist and engineer in the field of polymer materials, is a silicone factory brand. "Gang", or port, is a new place near sea for him to cultivate. "Tian", or field, stands for his hometown, a very small village in Hengyang, Hunan Province. Influenced by his parents who were both farmers, he creatively combines the company culture with Eastern wisdom, to work on the vision of "Making a better life with magic silicone rubber". With his efforts and achievements in R & D of silicone rubbers, we have been serving hundreds of domestic and overseas customers with quality materials for more than 15yrs. And now our production capacity reaches to more than 500tons per month. We uphold the core values of "create value for partners" and create value for e-commerce and information service industry through independent innovation and sincere co-op with "honesty, tolerance, innovation and service" as the spirit of enterprise. We always warmly welcome you to join us. Let's go and explore this magic world of silicones!

1kg/plastic can, 5kg/plastic drum , 20kg/metal drum, 25kg/ plastic drum, 25kg/ metal drum, 200kg/metal drum,

Customized service on package is available.

Normal delivery time is within 3-5days with confirmation on payment in our bank.

Please confirm with us if you need an urgent order.

- Shipments by sea, by air, by train, or by truck is available.

- Normal delivery time is within 3-5days with confirmation on payment in our bank.

- Please confirm with us if you need an urgent order.

Shelf lifeTwelve (12) months from date of shipment when stored at 25ºC in the original sealed packages.

FAQ

Q: Do you have a factory?

A:We have factory in Dongguan. As a leading manufacturer of silicone rubber in China, we are on the liquid silicon rubber market for more than 16 years, depends on our high quality products and best service.

Q: Is a free sample available?

A: Yes. Normally we can offer dear you 500g sample in free of charge.

Q: What's your delivery time like?

A: 3-5 working days after confirming your payment in our bank.

Warm Tips: 1 working day is for our technician to test the cargo and arrange the COA.

Our Contact