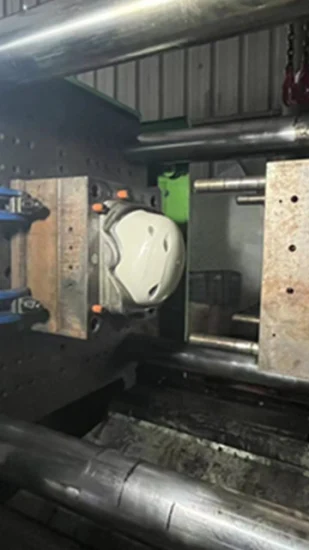

Hardness 30 Shore a Fumed Silicone Rubber for Extrusion Compression Molding Parts

Overview Package Size 25.00cm * 25.00cm * 25.00cm Package Gross Weight 1.000kg Food Grade Hardness 80 Shore A HTV Fumed

Description

Basic Info.

| Model NO. | Extrusion Grades 4 |

| Form | The Massive Raw Rubber |

| Tear Strength | 16 N/mm |

| Package | 20kgs/ Carton |

| Press Cure | 165ºC/10 Min |

| Curing Agent | C-5 0.9%(Wt.) |

| Transport Package | Bucket |

| Specification | Custom |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 50000 |

Packaging & Delivery

Package Size 25.00cm * 25.00cm * 25.00cm Package Gross Weight 1.000kgProduct Description

Food Grade Hardness 80 Shore A HTV Fumed Silicone Rubber For Extrusion ProductBasic Info.| BRTE30-EM | BRTE50-EM | BRTE70-EM | BRTE80-EM | |

| Appearance | translucent | translucent | translucent | translucent |

| Specific gravityat 25ºC | 1.1 | 1.15 | 1.18 | 1.2 |

| Hardness,shore A (JIS) | 30 | 50 | 70 | 80 |

| Tear strength(Die Bkgf/cm) | 12 | 25 | 25 | 24 |

| Tensile strength,Mpa | 6.5 | 7.8 | 8.5 | 7 |

| Elongation % | 650 | 600 | 500 | 300 |

Cured ConditionCuring agent: C-5 0.9%(wt.) Press cure: 165ºC/10 min Post cure: 200ºC 2hrs /4hrs

Product Description

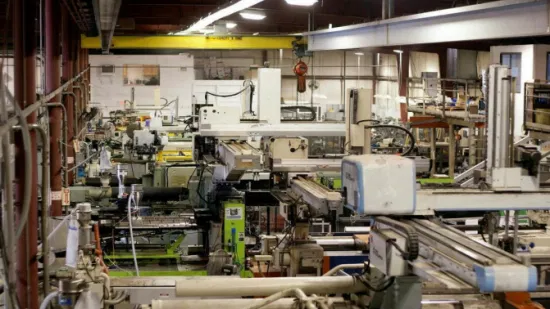

Company ProfileCertifications

Prev: Hot Selling Injection Molding Liquid Silicone Rubber for Adult Toy FDA LFGB Certification

Next: Precipitated Injection Molding Liquid Silicone Rubber with Hardness 20 30 40 70 80 Shore a

Our Contact

Send now