Mold Tool Maker Customized Silicone Rubber Injection/Press Compression Molding for O Ring Gaskets

Mold Tool Maker Customized Silicone Rubber Injection Compression MoldingCompression mold is a tool used for making silic

Description

Basic Info.

| Model NO. | Mold |

| Mould Life | 300000 Shots |

| Warranty | 1 Year |

| Customized | Customized |

| Rubber Products | EPDM/Silicone/NBR/Nitrile/Neoprene/Viton |

| Packing | Wooden Case |

| Mold Steel | #50, P20, S136 Heat Treat, 718h Steel etc. |

| Custom Mold | Liquid Silicone Injection Mold/Compressio Mold |

| Mold for | Keypad Buttons, Rubber Gaskets, Grommet, Seal |

| Mold Building | 3D Design or Sample |

| Transport Package | Wooden Case |

| Specification | Compression/LSR Injection/Transfer Molding |

| Trademark | Customized Embossed/Debossed Logo |

| Origin | Xiamen, China |

| Production Capacity | 60 Sets/Month |

Product Description

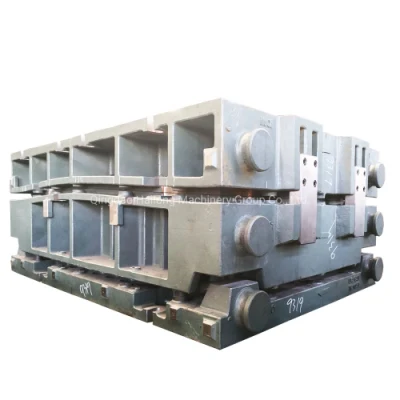

Mold Tool Maker Customized Silicone Rubber Injection Compression MoldingCompression mold is a tool used for making silicone rubber products/parts. Our company specialized in making precise mold tools/Transfer injection mold, liquid silicone injectio mold according to customer's design drawings, samples and quality demands.Technical Data

| 1 | Steel material | 45#,50#,2738,2343,DIN-1,S130,H13,2344,738H,718,8407,S136,NAK80,P20,KD-61,NIMAX ect |

| 2 | Steel hardness | 20-60HRC |

| 3 | Treatment | Pre-Harden, Nitriding, Heat treatment, Quenching |

| 4 | Cavity Qty | Single-cavity / Multi-cavity |

| 5 | Mould Life | 50K - 100k shots |

| 6 | Design Software | UG, CAD, 3D MAX, PRO-E, Solid Works etc, |

| 8 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish etc |

| 8 | Quality | ISO9001:2000 Certificate |

| 9 | Lead Time | 10-30 workdays depends on the different products |

| 10 | Package | Wooden Case Package or according to customer requirement |

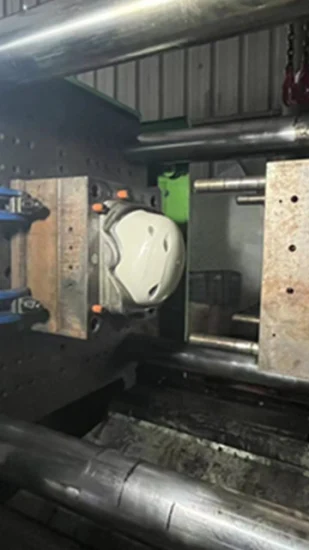

Rubber Compression MoldingLiquid Silicone Injection MoldingRubber Transfer Injection MoldingRubber Compression Mold StructuresSilicone Rubber Compression Mold with Movable Cores(ejecting mechanism: help to take out product from mold and avoid product from pulling injury/damage)Silicone Rubber Compression Mold with Keel(Mainly for some product with hollow-design structure)Silicone Rubber Compression Mold with Middle Plate(Mainly for some product with undercut-design structure) Two-Plate Compression Mold

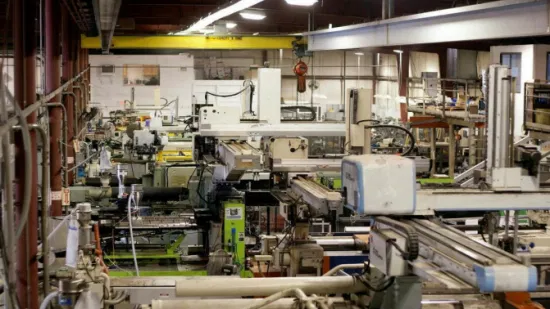

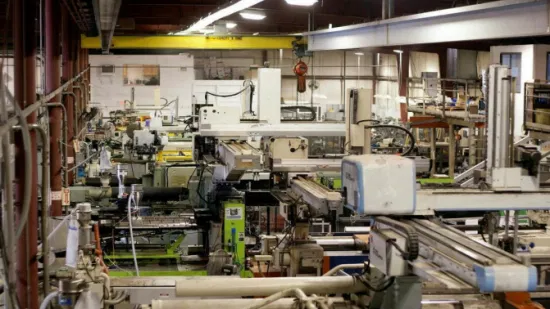

Quickly Quotation Demands For Rubber Mould1.2D/3D designs Drawings, Samples, or other basic information2.Materials Demands:Rubber ID(Rubber, Solid Silicone/LSR )3.Mold Cover/Base Steel Demands(or mold shot life).4. Surface Demands.5. Sizes Tolerance Demands: +/-0.005mm - +/-0.3mmOur FactoryXiamen Better Silicone Rubber Co., LTD, established in the year of 2018, is the production base of Xiamen Better Silicone Import and Export Co., LTD (established in 2015), who is specialized in manufacturing precision silicone rubber parts, LSR (liquid silicone rubber) parts and plastic components. Better Silicone aims at providing the comprehensive one-stop solutions and service throughout the entire production process, from product design analysis, mold design and mold making, sample & prototype, mass production stage and then ready-to-use products (finished product). Our Products can be widely used in Electronic Field, Medical Field, Auto parts & machinery parts field, etc.

Our Contact

Send now